Ihr 3D-Druck Partner

Maßgeschneiderte Lösungen mit 3D-Druck sind unser Spezialgebiet.

Durch die Funktionsweise der additiven Fertigung lassen sich komplexe Bauteile in einem Stück herstellen - das spart Zeit, Ressourcen und sorgt für mehr Effizienz.

Überwinden Sie mit uns die Design- und Produktionsgrenzen und schlagen Sie mit uns neue Wege in der industriellen Fertigung ein.

Lösungen mit 3D‑Druck – wo unsere Stärken liegen

Einzelteilanzahl reduzieren

Industrieller 3D-Druck bietet erhebliche Kostenvorteile gegenüber konventionellen Fertigungsverfahren.

Während Fräs- und Schweißteile oft in mehreren Schritten hergestellt werden müssen, können vergleichbare 3D-gedruckte Teile direkt einsatzbereit gefertigt werden.

Das Ergebnis: nur ein Bauteil muss gefertigt werden - weniger Montage, höhere Dichtigkeit und geringere Kosten.

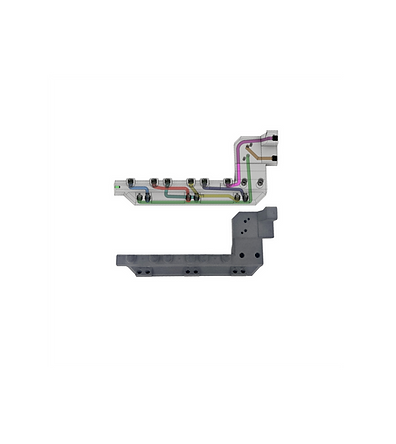

Innenliegende Kanäle & komplexe Geometrien

Besonders in der Serienfertigung bietet der 3D-Druck klare Vorteile: Komplexe Geometrien, wie Strömungs- oder Kühlkanäle mit kleinen Durchmessern lassen sich mit herkömmlichen Werkzeugen nicht herstellen oder reinigen. Mit HP Multi Jet Fusion fertigen wir innenliegende Kanäle ab Ø ~3 mm – auch verwinkelt oder verzweigt.

Sie profitieren von direkter Funktionsintegration ins Bauteil ohne aufwendige Nachbearbeitung.

Leichtbau für Greifer & Automatisierung

In der Automatisierung geben vor allem die Endeffektoren die Taktzeit vor. Durch topologieoptimierte Greifer (z.B. bei Joghurtbechern) lässt sich nicht nur Gewicht einsparen, sondern auch eine höhere Dynamik und Energieeinsparung generieren. Greifer können mit 3D-Druck schnell und einfach angepasst und gefertigt werden

Vorrichtungen & Werkzeuge

Fertigungs- und Prüfvorrichtungen, sowie Werkzeuge, müssen schnell verfügbar, ergonomisch und leicht sein. Die Lösung: 3D‑gedruckte Vorrichtungen mit integrierten Kabelkanälen, Sensoraufnahmen und Skalenprägungen.

Sie profitieren von kürzeren Entwicklungszeiten, besserer Handhabung und schnelleren Anpassungen.

Maßhaltigkeit & Toleranzen

Oft müssen enge Toleranzen, Passungen oder Dichtflächen bei Bauteilen oder Vorrichtungen beachtet werden. Durch gezielte CNC-Nachbearbeitung (Fräsen, Bohren, Gewinde) stellen wir Maßhaltigkeit sicher. Auf Wunsch liefern wir einen Messbericht – entweder für das reine 3D-Druckteil oder nach kompletter Bearbeitung.

Das Ergebnis: präzise Bauteile mit dokumentierter Qualität.

Oberflächen & Funktionale Details

Bauteile oder Vorrichtungen müssen technisch präzise und optisch hochwertig sein – oft mit zusätzlichen Markierungen oder Funktionen. Wir kombinieren Nachbearbeitung, Finish und Montage:

-

Lackieren & Beschichten: Serienfähige Endprodukte wie GPS-Antennen oder Gehäuse.

-

Prägung & Gravur: Skalen, Logos und funktionale Oberflächenstrukturen.

-

Baugruppen-Montage: Vormontage von Inserts, Dichtungen und mechanischen Komponenten.

-

Planfräsen: Herstellung absoluter Ebenheit, z. B. an Dichtflächen.

Für Bauteile, die technisch, funktional und optisch überzeugen – montagebereit und serientauglich.

Weitere Einsatzgebiete

-

Automotive & Luftfahrt: Leichtbaukomponenten, Montage‑Vorrichtungen, Funktionsprototypen

-

Maschinen‑ & Anlagenbau: Fluidführung, Kühlkanäle, Prüf‑ und Fertigungsvorrichtungen

-

Robotik & Automation: Greifer, Endeffektoren, ergonomische Werkzeuge

-

Interior Design & Architektur: Designobjekte, funktionale Einzelstücke, Kleinserien